Description

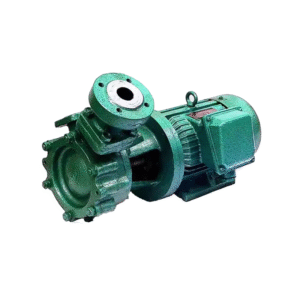

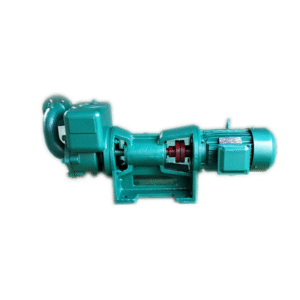

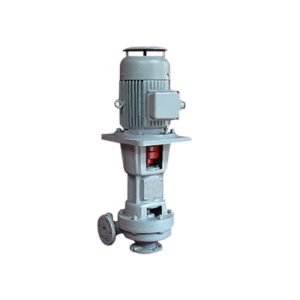

CYZ Series marine horizontal self-priming centrifugal oil pump

一、 General

CYZ Series marine horizontal self-priming centrifugal oil pump are used at boats and ships transport petrochemicals such as petrol, coal oil and diesel oil. The temperature of medium can be between 20degrees below zero and 80degrees. This series pump is a high quality marine cargo oil pump, it also be suitable oil transport to the land oil tanker and oil tanker car and so on. It is able to carry seawater and fresh water less than 80 degrees. When used non-corrosive mechanical seal it can be transport chemistry liquid.

The pump rotates anticlockwise viewd from motor.

二、Main technical parameter

| Serial Number | model | Flow m3/h |

扬程 m |

rotational speed r/min |

motor power kw |

Required net positive suction head (NPSH)r m |

| 1 | 40CYZ-20 | 6.3 | 20 | 2900 | 1.1 | 3.5 |

| 2 | 40CYZ-40 | 10 | 40 | 4 | ||

| 3 | 50CYZ-40 | 10 | 40 | |||

| 4 | 50CYZ-12 | 15 | 12 | 1.5 | ||

| 5 | 50CYZ-20 | 18 | 20 | 2.2 | ||

| 6 | 50CYZ-35 | 14 | 35 | 4 | ||

| 7 | 50CYZ-50 | 12.5 | 50 | 55 | ||

| 8 | 50CYZ-60 | 15 | 60 | 7.5 | ||

| 9 | 50CYZ-75 | 20 | 75 | 11 | ||

| 10 | 80CYZ-13 | 35 | 13 | 3.0 | 4 | |

| 11 | 80CYZ-17 | 43 | 17 | 4.0 | ||

| 12 | 80CYZ-25 | 50 | 25 | 7.5 | ||

| 13 | 80CYZ-32 | 50 | 32 | |||

| 14 | 80CYZ-55 | 60 | 55 | 18.5 | ||

| 15 | 80CYZ-70 | 60 | 70 | 22 | ||

| 16 | 100CYZ-40 | 80 | 45 | 5 | ||

| 17 | 100CYZ-40A | 100 | 40 | 1450 | 4 | |

| 18 | 100CYZ-40右 | 100 | 40 | |||

| 19 | 100CYZ-65 | 100 | 65 | 2900 | 30 | |

| 20 | 100CYZ-75 | 70 | 75 | |||

| 21 | 150CYZ-55 | 160 | 55 | 45 | 5 | |

| 22 | 150CYZ-65 | 170 | 65 | 1450 | 55 | |

| 23 | 150CYZ-80 | 150 | 80 | 2900 | 4.5 | |

| 24 | 200CYZ-63 | 280 | 63 | 1450 | 90 | 5 |

| 25 | 200CYZ-65 | 350 | 65 | 110 | ||

| 26 | 250CYZ-50 | 400 | 50 | 90 | ||

| 27 | 250CYZ-55 | 450 | 55 | 110 |

How to select a horizontal self-priming centrifugal oil pump?

1. First, confirm the medium and operating conditions (to determine if the pump can be centrifugal self-priming).

The following must be clearly stated:

Oil type: diesel, gasoline, kerosene, lubricating oil, heat transfer oil, etc. (whether it is volatile, whether it contains gas/water/impurities).

Temperature range: minimum/maximum (affects viscosity, vaporization pressure, seals, and materials).

Viscosity (cSt): Very critical.

Higher viscosity significantly reduces the flow rate, head, and efficiency of the centrifugal pump, and also worsens its self-priming performance.

Empirically: >50–100 cSt often recommends evaluating gear pumps/screw pumps; if a centrifugal pump is insisted upon, viscosity correction should be performed, and a larger pump size or speed reduction should be selected.

Solid content: Sand/iron filings accelerate wear, requiring filters or wear-resistant designs.

Leakage tolerance: Determines whether a mechanical seal, double-end seal, or magnetic pump solution is used.

2. Define Flow Rate Q and Head H (Pump “Operating Point”)

Flow Rate Q: Normal/Maximum/Minimum (m³/h or L/min).

Head H: Not simply “vertical height,” it must include:

Static head (including suction head/discharge head) + Pipeline friction loss + Local losses at elbows and valves + Pressure drop from filters/flowmeters/loading arms + Outlet back pressure (e.g., tank pressure).

Aim for the operating point as close as possible to the BEP region of the pump curve to avoid prolonged low flow rates (self-priming pumps are more prone to overheating at low flow rates).

3. Self-priming Capacity and Suction Pipeline (Determines “Whether it can be drawn up”)

The most common pitfalls with self-priming pumps are:

Pay attention to the self-priming height/self-priming time provided by the manufacturer, but consider the conditions (medium, speed, pipe diameter, whether it’s the first time priming). You need to calculate/confirm:

Actual suction height (height difference between liquid level and pump centerline)

Suction pipe losses (small pipe diameter, many bends, and clogged filters can all cause self-priming failure)

Oil volatility: Gasoline/light oils are more prone to cavitation and vapor lock, making self-priming more demanding.

Suction side recommendations:

Diameter not smaller than the pump inlet, as short, straight, and with few bends as possible

Suction pipe sloping upwards towards the pump to avoid air pockets

Whether a foot valve/check valve is needed: Many self-priming pumps do not require a foot valve, but long suction pipes or conditions prone to backflow may still require a check valve

Reserve a priming/exhaust port; priming should be performed as required during initial startup.

Reminder: Self-priming ≠ being able to pump dry for a long time. Most self-priming centrifugal pumps still require a certain amount of liquid in the pump chamber to form a liquid ring in order to establish a vacuum.

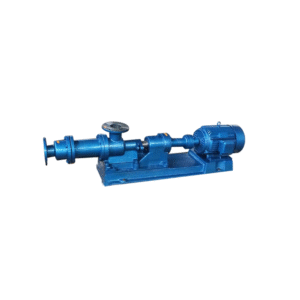

4. Structure selection: Choose the right “self-priming type”

Common horizontal self-priming centrifugal oil pump structures:

Gas-liquid separation external mixing type/self-priming chamber structure (common self-priming pumps): Suitable for intermittent pumping, where air may be introduced during suction.

Vacuum-assisted priming: More stable with high suction head and long pipelines (but system complexity).

Alternatives: Vane pumps/gear pumps/screw pumps are often more suitable for high viscosity or when stronger self-priming and stable metering are required.

5.Materials, Seals, and Explosion-proof (essential for oil pumps)

Materials: Commonly used for pump bodies are cast iron/ductile iron; stainless steel can be selected for sulfur-containing or corrosive materials, or for applications requiring higher cleanliness. Seal materials must be matched to the oil type and temperature (NBR/FKM/PTFE, etc.). Mechanical Seal: Normal Operating Conditions: Single-face mechanical seal. Volatile/Zero Leakage Required/Environmentally Friendly: Consider double-face mechanical seals (API Plan) or magnetic pumps (but magnetic pumps also require attention to viscosity and dry-running risks). Explosion-proof: Motors generally need to meet site requirements: Ex d / Ex e, etc. (select according to the area’s explosion-proof rating). Static grounding, coupling protection, venting, and ventilation should also be considered.

6. Temperature Rise, Backflow, and Protection (Self-priming oil pumps are prone to “stuck pump overheating”) Oils with low specific heat and high viscosity are more prone to temperature rise:

Long-term operation with the outlet valve partially closed is not recommended; add minimum flow backflow/bypass if necessary.

Configuration: Outlet pressure gauge, temperature protection, dry-running/idle-running protection (liquid level interlock, power/vibration monitoring, etc.)

7. Key acceptance points (to be specified in the technical specifications before purchase): Performance curves for your medium at different viscosities and temperatures (Q-H, efficiency, power, NPSHr, self-priming height/time); Allowable suction head and self-priming time (with piping conditions); Sealing type and leakage rating; Explosion-proof certificate, material report, test report; Spare parts list (mechanical seals, bearings, wear rings, etc.).

Reviews

There are no reviews yet.