Description

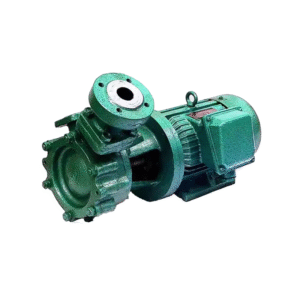

CXZ Series marine self-priming vortex pump

CXZ Series marine self-priming are applicable to pumping fresh and sea water for drinking washing and sanitary uses in vessels.

The pump rotates clockwise viewed from motor.

一、Pump model and performance parameters:

| Specifications and Models | 流量 m3/h |

扬程 m h2o |

吸入高度 m |

转速 r/min |

电机功率 kw |

泵质量 kg |

| 20CXZ-35 | 1 | 35 | 3 | 2900 | 0.75 | 52 |

| 32CXZ-25 | 3.5 | 28 | 3 | 2900 | 1.5 | 57 |

| 32CXZ-40 | 3 | 40 | 4 | 2900 | 2.2 | 57 |

| 40CXZ-30 | 9 | 30 | 4 | 2900 | 4 | 80 |

Why select a suction vortex pump?

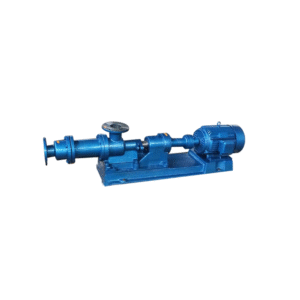

Self-priming vortex pumps combine strong self-priming capability with high head, making them particularly suitable for the following marine applications:

* Bulch pumps: Pumping residual water from the bilge, which may contain small amounts of oil and air.

* Sanitary water pumps: Discharging domestic sewage.

* Daily seawater/freshwater pressurization: Supplying water from lower-level daily storage tanks to higher levels.

* Diesel fuel delivery: Supplying fuel from oil drums or lower-level fuel tanks to the main engine and generator.

1. Confirm Core Performance Parameters

Self-priming Performance & Self-priming Time:

This is the most important indicator. Inquire with the supplier about the “self-priming time” required to reach the rated flow rate under standard operating conditions (e.g., suction lift 5-6 meters). This is typically between tens of seconds and two minutes. Shorter time is better.

Maximum Self-priming Height: Theoretically, it can reach 5-8 meters, but in practical applications, considering pipeline losses, it is recommended to keep it within 4-5 meters.

Flow Rate and Head: Vortex pumps are characterized by low flow rates and high heads. Determine based on your system requirements.

Note: The performance curve of a self-priming vortex pump shows a higher head in the low flow rate range, but prolonged operation with the outlet valve completely closed should be avoided to prevent liquid overheating.

Media Characteristics:

Cleanliness: Although it is more tolerant than ordinary vortex pumps, it is still not an impurity pump. It can only tolerate trace amounts of fine, soft particles. If the medium contains a large amount of solid particles (such as silt), a filter must be installed in the suction pipe.

Corrosivity: When conveying seawater, diesel fuel, domestic sewage, etc., corrosivity must be considered.

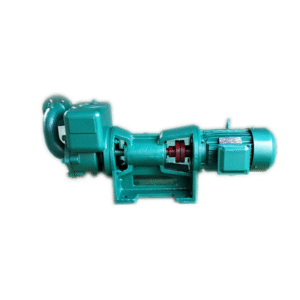

2. Special Requirements for Structure and Materials

Pump Body and Impeller Materials:

Seawater/Oily Wastewater: Stainless steel (e.g., 304, 316L) or bronze are preferred.

Diesel Diesel Pumping: Cast iron (low cost) or stainless steel are acceptable. Ensure material compatibility with the medium.

Sanitary Water Pumps (Domestic Sewage): Stainless steel is recommended for its ease of cleaning and corrosion resistance.

Sealing Type (Crucial):

Mechanical Seal: The preferred choice for marine applications, with low leakage, long lifespan, and extended maintenance-free periods. Ensure its material (e.g., silicon carbide/ceramic matte surface) can withstand the pumped medium.

Stuffing Seal: Inexpensive and resistant to minor wear, but may leak slightly, requiring periodic adjustment or replacement. Not recommended in situations where leakage is unacceptable (e.g., engine room bottom).

Reservoir and Gas-Liquid Separation Chamber: Self-priming pumps have a built-in reservoir for initial priming and gas-liquid separation during self-priming. Ensure a reasonable structural design and high self-priming efficiency.

3. Marine Environmental Compatibility

Classification Society Certification: For critical marine systems, pumps must be certified by relevant classification societies, such as China CCS, USA ABS, Norway DNV, and Germany GL. This is a guarantee of safety and quality.

Motor Characteristics:

Explosion-proof Rating: If used for conveying fuel oil or located in hazardous areas (such as the engine room), the motor must meet explosion-proof standards (such as Ex d IIC T4).

Protection Rating: At least IP55 to prevent water and dust ingress. IP56 or higher is recommended to withstand harsh environments such as deck washing.

Voltage and Frequency: Match the marine electrical system; common values are 380V/50Hz, 440V/60Hz, etc.

Installation and Connection: Confirm that the installation method (base-mounted/flange-mounted), inlet/outlet diameter, and direction are compatible with the ship’s piping layout.

4. Brand, Maintenance, and Economy

Brand and After-sales Service: Choose a brand with a good reputation in the marine industry to ensure that spare parts and technical support are available in ports worldwide.

Ease of maintenance: Check whether the pump is easy to disassemble and repair, and whether it is convenient to replace the mechanical seal or impeller.

Selection Process Summary

Define Operating Conditions: Clearly define “what to pump (medium), how much to pump (flow rate), how high to pump (head), and from where to pump (priming height).”

Example: Used as a bilge pump to pump seawater containing a small amount of oil. The required flow rate is 8 m³/h, the required head is 60 meters, and the priming height is approximately 4 meters.

Initial Pump Selection: Based on the flow rate-head parameters, find the corresponding point on the performance curve of the self-priming vortex pump to confirm the model.

Material and Sealing Verification: Select a 316 stainless steel pump body and an oil-resistant mechanical seal based on the medium (oil-containing seawater).

Certification and Motor Check: Confirm CCS certification, IP56 motor protection rating, and explosion-proof rating meeting engine room requirements.

Installation Details Confirmation: Verify flange standards, base dimensions, and motor rotation direction.

Important Notes: Priming is mandatory for first start-up: Although called “self-priming,” the pump chamber must be filled with liquid (storage chamber) before the first start-up. Do not dry run: Even with self-priming capability, prolonged dry running will damage the mechanical seal and pump.

Regular checks: Check the liquid level in the reservoir and perform regular maintenance on the mechanical seal and filter.

Reviews

There are no reviews yet.