Description

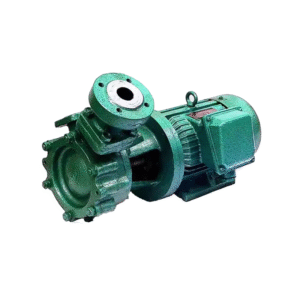

W Series marine horizontal Swirl pump

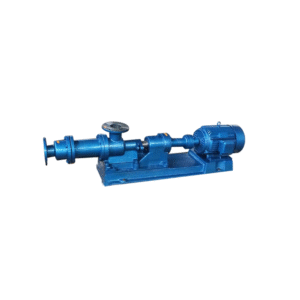

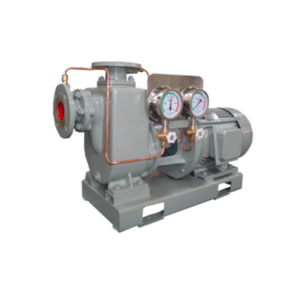

The CWZ series marine horizontal self-priming centrifugal pumps are suitable for use as ballast pumps, bilge pumps, cooling pumps, fire pumps, and general-purpose pumps on ships. They can be used to transport seawater, fresh water, and other non-corrosive liquid media with temperatures not exceeding 80℃.

The pump rotates counter-clockwise when viewed from the drive end.

二、Pump model and performance parameters:

| Serial Number | model | Traffic m3/h |

扬 程 m |

speed r/min |

motor power kW |

Required Net Positive Suction Head (NPSH) (NPSH)r m |

| 1 | 32CWZ-5 | 8 | 21 | 2950 | 1.5 | 4.0 |

| 2 | 32CWZ-4 | 30 | 2.2 | |||

| 3 | 32CWZ-3 | 42 | 4.0 | |||

| 4 | 40CWZ-6 | 12 | 21 | 2.2 | ||

| 5 | 40CWZ-5 | 30 | 3.0 | |||

| 6 | 40CWZ-4 | 42 | 4.0 | |||

| 7 | 50CWZ-8 | 21 | 21 | 3.0 | ||

| 8 | 50CWZ-6 | 30 | 4.0 | |||

| 9 | 50CWZ-5 | 42 | 5.5 | 5.0 | ||

| 10 | 65CWZ-11 | 36 | 21 | 4.0 | 4.0 | |

| 11 | 65CWZ-8 | 30 | 5.5 | |||

| 12 | 65CWZ-6 | 42 | 11.0 | 5.0 | ||

| 13 | 65CWZ-5 | 60 | 15.0 | |||

| 14 | 80CWZ-14 | 60 | 21 | 7.5 | 4.0 | |

| 15 | 80CWZ-11 | 30 | 11.0 | |||

| 16 | 80CWZ-8 | 42 | 15.0 | 5.0 | ||

| 17 | 80CWZ-6 | 60 | 22.0 | |||

| 18 | 80CWZ-5.5 | 75 | 30.0 | |||

| 19 | 100CWZ-18 | 100 | 21 | 11.0 | ||

| 20 | 100CWZ-14 | 30 | 15.0 | |||

| 21 | 100CWZ-11 | 42 | 30 | |||

| 22 | 100CWZ-8 | 60 | 37 | |||

| 23 | 100CWZ-6 | 85 | 55 | |||

| 24 | 150CWZ-16 | 180 | 30 | 37 | ||

| 25 | 150CWZ-22 | 200 | 25 | 37 | ||

| 26 | 200CWZ-15 | 300 | 25 | 1450 | 37 | 6.5 |

| 27 | 250CWZ-20 | 550 | 22 | 75 | 6.0 |

How to select a marine horizontal self-priming centrifugal pump?

1.First, clarify the purpose and medium (determine the material, seal, and structure).

Common applications of marine self-priming centrifugal pumps: bilge drainage, ballast/drainage, fire-fighting water intake assistance, domestic/flushing, priming for seawater cooling circulation, etc.

Required confirmation:

Media: Seawater/fresh water/oily wastewater/liquid containing sand/high gas content?

Temperature range: Normal temperature or hot water (affects sealing and temperature resistance).

Corrosivity: Seawater typically requires higher corrosion-resistant materials.

Solid particles: Particle size and content (affects whether to select a “sewage self-priming pump/large-channel impeller/with cutter”).

Recommendations:

Seawater: Prioritize seawater-resistant materials (e.g., duplex stainless steel, 316L, bronze/aluminum bronze, etc., depending on shipyard and specifications).

Oil/wastewater: Consider oil-resistant rubber and matching mechanical seal materials, and select an impeller/pump chamber structure that is not prone to clogging.

2. Key Operating Parameters (Determine Model Size)

At least these four items are required:

Flow Rate Q (m³/h): Calculated based on system requirements or piping; a 10-20% margin is recommended.

Head H (m): Includes static head + piping friction/local losses + terminal pressure requirements.

Suction Head/Suction Conditions: This is crucial for the stable operation of the self-priming pump.

Suction pipe length, diameter, number of bends, and potential for air leakage.

Available installation height on site (relative height between pump centerline and liquid surface).

Speed/Power Supply: Commonly used on ships is 380/440V, 50/60Hz; motor protection and explosion-proof rating requirements.

Important Reminder: A higher “self-priming height” is not always better; the actual performance depends more on whether the NPSHa (Net Positive Hypothesis Ha) is met. High seawater temperature, thin and long suction pipes, and numerous bends can all easily lead to cavitation, noise, and unstable flow.

3. Self-priming performance and “self-priming time” should be compared with operating conditions. Obtain these data from the manufacturer when selecting a pump:

Maximum self-priming height (at a certain speed and temperature)

Self-priming time (e.g., how long does it take to draw water up at a 4-6m suction head)

Is initial priming/pre-filling required? Most self-priming centrifugal pumps require priming fluid to be retained in the pump body initially; if the pump is to be shut down for an extended period, repriming or the addition of a foot valve/priming device may be necessary.

Dry-running resistance: Dry-running is generally not recommended; if dry-running is possible, consider adding dry-running protection or selecting a more dry-running resistant sealing solution.

4. Materials and corrosion protection (crucial for marine applications)

Pump body/impeller/shaft: Is cast iron + anti-corrosion coating sufficient? Higher grade materials are recommended for seawater.

Fasteners, bushings: Stainless steel grade.

Coating system: Does it meet marine corrosion protection standards (salt spray, seawater resistance)? For bilge/sewage applications, also consider:

Wear-resistant bushings, replaceable wear rings

Large-channel impeller (anti-clogging)

Filter screen/basket filter configuration

5. Seals and bearings (determine reliability and maintenance requirements)

Mechanical seal: Single-end/double-end? Material (silicon carbide/tungsten carbide/graphite, etc.) and rubber (NBR/FKM/EPDM) must be compatible with the medium.

Is flushing/cooling required (Plan 11/32, etc.)? – If the medium contains sand or has a high temperature, the seal needs extra protection.

Bearing life, lubrication method, and ease of maintenance.

6. Installation type and piping compatibility (avoid “choosing the right pump but using it poorly”)

Suction pipe should be as short, thick, with few bends, and well-sealed as possible; avoid high-point air accumulation at the suction inlet.

It is recommended to add an **eccentric reducer (flat-top)** to the suction pipe to prevent air pockets.

Is a foot valve required? Many self-priming pumps do not require a foot valve, but if the suction pipe is prone to slippage or the system needs to maintain priming, a foot valve/check valve can improve the success rate (while assessing resistance loss and clogging risk).

Base and coupling: For horizontal pumps, alignment should be easy and vibration damping measures adequate.

7. Certifications and standards (often required onboard)

Is classification society certification required: CCS/ABS/DNV/LR/BV, etc.?

Motor: Marine motor, IP rating, insulation class, explosion-proof (Ex may be required in engine room/oil tank areas).

Noise and vibration requirements (required for some ship types or projects).

8. Recommended configuration (to improve usability)

Inlet filter (depending on media cleanliness)

Outlet check valve + gate valve/butterfly valve

Pressure gauge, vacuum gauge (for cavitation/clogging detection)

Dry run/water shortage protection, temperature rise protection

Spare parts package: mechanical seal, bearings, O-rings, vulnerable parts

Reviews

There are no reviews yet.