Description

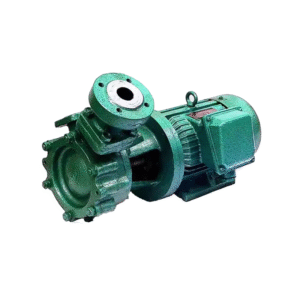

CWL Series marine horizontal centrifugal pump

一、General

CWL Series marine horizontal centrifugal pumps are applicable to fire control、cooling and Sanitation and applied to industries, to city water supply and drain, and also to agricultural and orchard irrigation.

二、main technical parameter

| Serial Number | model | 流量 m3/h |

扬程 m |

转速 r/min |

电机功率 kw |

Required net positive suction head (NPSH)r m |

| 1 | 32CWL-4 | 4 | 21 | 2950 | 1.1 | 4 |

| 2 | 32CWL-3 | 4 | 30 | 2950 | 1.5 | 4 |

| 3 | 40CWL-5 | 8 | 21 | 2950 | 1.1 | 4 |

| 4 | 40CWL-4 | 8 | 30 | 2950 | 2.2 | 4 |

| 5 | 40CWL-3 | 8 | 42 | 2950 | 3 | 4 |

| 6 | 50CWL-6 | 12 | 21 | 2950 | 1.5 | 4 |

| 7 | 50CWL-4.5 | 12 | 30 | 2950 | 3 | 4 |

| 8 | 50CWL-4 | 12 | 42 | 2950 | 4 | 4 |

| 9 | 50CWL-8 | 21 | 21 | 2950 | 3 | 4 |

| 10 | 50CWL-7 | 21 | 30 | 2950 | 4 | 4 |

| 11 | 50CWL-5 | 21 | 42 | 2950 | 5.5 | 5 |

| 12 | 50CWL-3.5 | 21 | 60 | 2950 | 7.5 | 5 |

| 13 | 65CWL-11 | 35 | 21 | 2950 | 4 | 4 |

| 14 | 65CWL-8 | 35 | 30 | 2950 | 5.5 | 4 |

| 15 | 65CWL-6 | 35 | 42 | 2950 | 7.5 | 5 |

| 16 | 80CWL-14 | 60 | 21 | 2950 | 5.5 | 4 |

| 17 | 80CWL-11 | 60 | 30 | 2950 | 7.5 | 4 |

| 18 | 80CWL-8 | 60 | 42 | 2950 | 15 | 5 |

| 19 | 80CWL-6 | 60 | 60 | 2950 | 18.5 | 5 |

| 20 | 80CWL-5.5 | 60 | 75 | 2950 | 22 | 3.8 |

| 21 | 100CWL-18 | 100 | 21 | 2950 | 11 | 4 |

| 22 | 100CWL-14 | 100 | 30 | 2950 | 15 | 4 |

| 23 | 100CWL-11 | 100 | 42 | 2950 | 18.5 | 5 |

| 24 | 100CWL-8 | 100 | 60 | 2950 | 30 | 5 |

| 25 | 100CWL-6 | 100 | 85 | 2950 | 45 | 5 |

| 26 | 150CWL-16 | 200 | 60 | 1450 | 55 | 4.5 |

How to select a marine horizontal centrifugal pump?

Step 1: Define Application Requirements (Selection Basis)

1. Determine the Pumping Medium

Clean Liquids: Such as seawater (for central coolers), fresh water (low-temperature/high-temperature fresh water circulation), distilled water. Closed impellers are the most efficient.

Slightly Contaminated Liquids: Such as bilge water (may contain oil and small amounts of impurities). Bilge pumps with open or semi-open impellers are required, or a filter should be added to a closed impeller pump.

Viscous Liquids: Such as fuel oil, lubricating oil. The impact of viscosity on performance (flow rate, head, power) must be considered; performance curves usually need to be adjusted.

2. Determine Key Performance Parameters

Flow Rate: The required liquid delivery volume of the system (m³/h).

Head: The total resistance the pump needs to overcome (including static head, pipeline friction losses, valve/equipment resistance), in meters (m).

Operating Temperature: The temperature range of the medium, affecting material selection and sealing methods.

3. Installation Conditions

Net Positive Suction Head: This is one of the decisive factors in selecting a horizontal centrifugal pump.

Backflow installation: The pump inlet centerline is below the liquid level. In this case, the system’s effective net positive suction head (NPSHa) is sufficient, representing the ideal operating condition.

Suction-mounted installation: The pump inlet centerline is above the liquid level. It is essential to strictly calculate NPSHa > the pump’s required net positive suction head (NPSHr) + safety margin (typically ≥0.5m); otherwise, cavitation will occur, damaging the pump.

Step 2: In-depth Technical Specification Selection

1. Pump Type and Structure Selection

Single-stage vs. Multi-stage:

Single-stage horizontal centrifugal pump: Most common, suitable for low to medium head (usually ≤150m). Simple structure, low cost, and easy maintenance. Examples include central cooling water pumps, daily seawater pumps, freshwater pumps, and general cooling pumps.

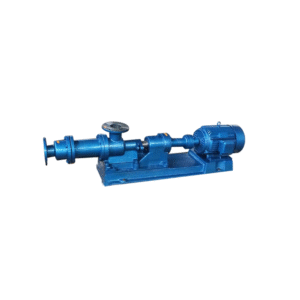

Multi-stage horizontal centrifugal pump: Suitable for high head conditions. Achieved through multiple impellers in series, resulting in a longer structure and higher cost. Examples include high-pressure deck flushing pumps and boiler feed pumps.

Impeller Type:

Closed impeller: Highest efficiency, suitable for clean liquids. The vast majority of marine horizontal pumps use this type.

Open/Semi-open impeller: Less prone to clogging, suitable for liquids containing a small amount of solid particles, but with lower efficiency. Commonly used for bilge water and sewage.

2. Material Selection (Corrosion Resistance/Abrasion Resistance)

Seawater Medium:

Pump casing/impeller: Bronze or stainless steel (304, 316L). 316L steel has become the preferred choice for modern ships due to its excellent resistance to chloride corrosion.

Shaft: At least 2Cr13 or stainless steel.

Fresh water media: Cast iron can be used (low cost), but bronze or stainless steel is still recommended for high-quality systems.

Fuel/lubricating oil: Cast iron or cast steel can be used.

3. Shaft Sealing System (Critical Reliability Component)

Mechanical Seals (Absolute Mainstream and Preferred):

Single-face mechanical seals: Suitable for clean media, such as seawater and fresh water. High reliability, minimal leakage.

Double-face mechanical seals: Systems with isolation fluid (Plan 53A, etc.) are used for hazardous, expensive, or media where leakage is absolutely unacceptable. Highest safety.

Material: Silicon carbide to silicon carbide is recommended for the friction pair (dynamic/static rings), especially for abrasive media such as seawater, offering excellent wear resistance.

Stuffing seals (Gradually being phased out):

Advantages: Low cost, tolerates slight wear.

Disadvantages: Continuous micro-leakage (requires adjustment to a few drops per minute), requiring regular maintenance. Not suitable for modern marine engine rooms.

4. Bearings and Lubrication

Bearings: Typically deep groove ball bearings (for radial forces) and angular contact ball bearings (for axial forces).

Lubrication Methods:

Grease lubrication: Simple and clean, the preferred choice for most standard pumps.

Oil lubrication: Better heat dissipation, used for heavy-duty, high-speed, or large pumps.

5. Drives and Connections

Motor:

Marine Certification: Must comply with classification society requirements.

Protection Class: Minimum IP55, IP56/IP66 recommended.

Insulation Class: Class F standard.

Explosion-proof Requirements: Determine whether an explosion-proof motor is required based on the installation location (e.g., near a pump pumping fuel oil).

Couplings: Use flexible couplings (e.g., star-shaped, nylon pin type) to compensate for alignment errors and mitigate shock and vibration.

Step 3: Compliance with Ship Codes and Installation Requirements

1. Classification Society Certification (Mandatory): The pump and motor, as a whole unit, must obtain type approval from the classification society to which the target vessel is registered. Examples include CCS (China), DNV (Norway), ABS (USA), and LR (UK). This is the bottom line for safety and quality.

2. Installation and Piping Design

Foundation: The pump unit should be installed on a sturdy, level common base and precisely aligned.

Suction Piping: For suction operation, it should be as short, straight, and large-diameter as possible, minimizing bends and valves.

It is recommended to install a filter before the inlet and ensure it is easy to clean.

The entire suction piping must be tightly sealed to prevent air leakage.

Outlet Piping: Install a check valve to prevent backflow and water hammer during shutdown; install an isolation valve for maintenance.

3. Vibration and Noise: Select a well-designed pump with high dynamic balancing accuracy to ensure smooth operation and compliance with classification society limits for vibration and noise.

Key Warnings and Recommendations:

**Never Run Dry:** Centrifugal pumps must never be started or run without liquid, as this will instantly damage the mechanical seal and bearings.

**Low Flow Rate Caution:** Avoid prolonged operation at flow rates far below the rated value (e.g., with the outlet valve closed), as this will cause the liquid to overheat and vaporize.

**Professional Matching:** Compile your detailed technical parameters into a Technical Specification Sheet and submit it to a professional marine pump supplier for final selection and matching. Their performance curves and certification documents are crucial for your decision.

Reviews

There are no reviews yet.