Description

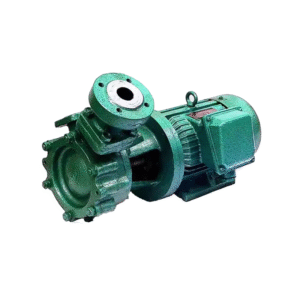

CIS、CIR Series marine horizontal centrifugal pump

一、General

CIS Series mqrine horizontal centrifugal pump is widely used for transfer of freshwater, seawater. The pumps are applicable to fire control, cooling and sanitation and applied to industries, to city water supply and drain, and also to agricultural and orchard irrigation.

CIR Series pump shall be used for circulation of hot water. When used to pump hot water not higher than 150℃.

The Performance parameters and installation dimensions of CIR Series pumps are the same as CI Series pumps.

The pump rotates clockwise viewed from motor.

二、main technical parameter

| model | 转速 r/min |

流量 m3/h |

扬程 m |

电机功率 kw |

(NPSH)r m |

单泵质量 kg |

model | 转速 r/min |

流量 m3/h |

扬程 m |

电机功率 kw |

(NPSH)r m |

单泵质量 kg |

| CIS50-32-125 | 2900 | 7.5 | 22 | 2.2 | 2 | 29 | CIS65-50-125 | 2900 | 15 | 21.8 | 3 | 2 | 35 |

| 12.5 | 20 | 2 | 25 | 20 | 2.5 | ||||||||

| 15 | 18.5 | 2.5 | 30 | 18.5 | 3 | ||||||||

| 1450 | 3.75 | 5.4 | 0.55 | 2 | 1450 | 7.5 | 5.35 | 0.55 | 2 | ||||

| 6.3 | 5 | 2 | 12.5 | 5 | 2 | ||||||||

| 7.5 | 4.6 | 2.5 | 15 | 4.7 | 2.5 | ||||||||

| CIS50-32-125A | 2900 | 11 | 15 | 1.5 | 2 | CIS65-50-125A | 2900 | 22 | 15 | 2.2 | 2 | ||

| 1450 | 5.5 | 3.7 | 0.55 | 2 | 1450 | 11 | 3.7 | 5.5 | 2 | ||||

| CIS50-32-160 | 2900 | 7.5 | 34.3 | 3 | 2 | 40 | CIS65-50-160 | 2900 | 15 | 34 | 4 | 2 | 42 |

| 12.5 | 32 | 2 | 25 | 32 | 2 | ||||||||

| 15 | 29.6 | 2.5 | 30 | 31 | 2.5 | ||||||||

| CIS50-32-160 | 1450 | 3.75 | 8.5 | 0.55 | 2 | 40 | CIS65-50-160 | 1450 | 7.5 | 8.5 | 0.75 | 2 | 42 |

| 6.3 | 8 | 2 | 12.5 | 8 | 2 | ||||||||

| 7.5 | 7.5 | 2.5 | 15 | 7.2 | 2.5 | ||||||||

| CIS50-32-160A | 2900 | 11 | 24 | 3 | 2 | CIS65-50-160A | 2900 | 22 | 24 | 3 | 2.5 | ||

| 1450 | 5.5 | 6 | 0.55 | 2 | 1450 | 11 | 6 | 0.55 | 2 | ||||

| CIS50-32-200 | 2900 | 7.5 | 52.5 | 5.5 | 2 | 45 | CIS65-40-200 | 2900 | 15 | 53 | 7.5 | 2 | 46 |

| 12.5 | 50 | 2 | 25 | 50 | 2 | ||||||||

| 15 | 48 | 2.5 | 30 | 47 | 2.5 | ||||||||

| 1450 | 3.75 | 13.1 | 0.75 | 2 | 1450 | 7.5 | 13.2 | 1.1 | 2 | ||||

| 6.3 | 12.5 | 2 | 12.5 | 12.5 | 2 | ||||||||

| 7.5 | 12 | 2.5 | 15 | 11.8 | 2.5 | ||||||||

| CIS50-32-200A | 2900 | 11 | 38 | 4 | 2 | CIS65-40-200A | 2900 | 22 | 38 | 5.5 | 2 | ||

| 1450 | 5.5 | 9.5 | 0.55 | 2 | 1450 | 11 | 9.5 | 0.75 | 2 | ||||

| CIS50-32-25 | 2900 | 7.5 | 82 | 11 | 2 | 79 | CIS65-40-250 | 2900 | 15 | 82 | 15 | 2 | 82 |

| 12.5 | 80 | 2 | 25 | 80 | 2 | ||||||||

| 15 | 78.5 | 2.5 | 30 | 78 | 2.5 | ||||||||

| 1450 | 3.75 | 20.5 | 1.5 | 2 | 1450 | 7.5 | 21 | 2.2 | 2 | ||||

| 6.3 | 20 | 2 | 12.5 | 20 | 2 | ||||||||

| 7.5 | 19.5 | 3 | 15 | 19.4 | 2.5 | ||||||||

| CIS50-32-250A | 2900 | 11 | 61 | 7.5 | 2 | CIS65-40-250A | 2900 | 22 | 61 | 11 | 2 | ||

| 1450 | 5.5 | 15.3 | 1.1 | 2 | 1450 | 11 | 15.3 | 1.5 | 2 | ||||

| CIS65-40-315 | 2900 | 15 | 127 | 30 | 2.5 | 90 | CIS80-50-250 | 2900 | 30 | 84 | 22 | 2.5 | 84 |

| CIS65-40-315 | 2900 | 15 | 127 | 30 | 2.5 | 90 | CIS80-50-250 | 2900 | 30 | 84 | 22 | 2.5 | 84 |

| 25 | 125 | 2.5 | 50 | 80 | 2.5 | ||||||||

| 30 | 123 | 3 | 60 | 75 | 3 | ||||||||

| 1450 | 7.5 | 32.3 | 4 | 2.5 | 1450 | 15 | 21 | 3 | 2.5 | ||||

| 12.5 | 32 | 2.5 | 25 | 20 | 2.5 | ||||||||

| 15 | 31.7 | 3 | 30 | 18.8 | 3 | ||||||||

| CIS65-40-315A | 2900 | 22 | 97 | 22 | 2.5 | CIS80-50-250A | 2900 | 45 | 61 | 18.5 | 2.5 | ||

| 1450 | 11 | 24 | 3 | 2.5 | 1450 | 22 | 15.3 | 2.2 | 2.5 | ||||

| CIS80-65-125 | 2900 | 30 | 22.5 | 5.5 | 3 | 44 | CIS80-50-315 | 2900 | 30 | 128 | 37 | 2.5 | 109 |

| 50 | 20 | 3 | 50 | 125 | 2.5 | ||||||||

| 60 | 18 | 3.5 | 60 | 123 | 3 | ||||||||

| 1450 | 15 | 5.6 | 0.75 | 2.5 | 1450 | 15 | 32.5 | 5.5 | 2.5 | ||||

| 25 | 5 | 2.5 | 25 | 32 | 2.5 | ||||||||

| 30 | 4.5 | 3 | 30 | 31.5 | 3 | ||||||||

| CIS80-65-125A | 2900 | 45 | 15 | 4 | 3 | CIS80-50-315A | 2900 | 45 | 97 | 30 | 2.5 | ||

| 1450 | 22 | 3.7 | 0.55 | 2.5 | 1450 | 22 | 24 | 4 | 2.5 | ||||

| CIS80-65-160 | 2900 | 30 | 36 | 7.5 | 2.5 | 43 | CIS100-80-125 | 2900 | 60 | 24 | 11 | 4 | 45 |

| 50 | 32 | 2.5 | 100 | 20 | 4.5 | ||||||||

| 60 | 29 | 3 | 120 | 16.5 | 5 | ||||||||

| 1450 | 15 | 9 | 1.5 | 2.5 | 1450 | 30 | 6 | 1.5 | 2.5 | ||||

| 25 | 8 | 2.5 | 50 | 5 | 2.5 | ||||||||

| 30 | 7.2 | 3 | 60 | 4 | 3 | ||||||||

| CIS80-65-160A | 2900 | 45 | 24 | 5.5 | 2.5 | 43 | CIS100-80-125A | 2900 | 90 | 15 | 7.5 | 4.5 | 45 |

| 1450 | 22 | 6 | 1.1 | 2.5 | 1450 | 45 | 3.7 | 1.1 | 2.5 | ||||

| CIS80-50-200 | 2900 | 30 | 53 | 15 | 2.5 | 46 | CIS100-80-160 | 2900 | 60 | 36 | 15 | 3.5 | 63 |

| 50 | 50 | 2.5 | 100 | 32 | 4 | ||||||||

| 60 | 47 | 3 | 120 | 28 | 5 | ||||||||

| 1450 | 15 | 13.2 | 2.2 | 2.5 | 1450 | 30 | 9.2 | 2.2 | 2 | ||||

| 25 | 12.5 | 2.5 | 50 | 8 | 2.5 | ||||||||

| 30 | 11.8 | 3 | 60 | 6.8 | 3.5 | ||||||||

| CIS80-50-200A | 2900 | 45 | 38 | 11 | 2.5 | CIS100-80-160A | 2900 | 90 | 24 | 11 | 4 | ||

| 1450 | 22 | 9.5 | 1.5 | 2.5 | 1450 | 45 | 6 | 1.5 | 2.5 | ||||

| CIS100-65-200 | 2900 | 60 | 54 | 22 | 3 | 65 | CIS125-100-250 | 2900 | 120 | 87 | 75 | 3.8 | 129 |

| 100 | 50 | 3.6 | 200 | 80 | 4.2 | ||||||||

| 120 | 47 | 4.8 | 240 | 72 | 5 | ||||||||

| 1450 | 30 | 13.5 | 4 | 2 | 1450 | 60 | 21.5 | 11 | 2.5 | ||||

| 50 | 12.5 | 2 | 100 | 20 | 2.5 | ||||||||

| 60 | 11.8 | 2.5 | 120 | 18.5 | 3 | ||||||||

| CIS100-65-200A | 2900 | 90 | 38 | 18.5 | 3.6 | CIS125-100-250A | 2900 | 180 | 61 | 55 | 4.2 | ||

| 1450 | 45 | 9.5 | 3 | 2 | 1450 | 90 | 15.3 | 7.5 | 2.5 | ||||

| CIS100-65-250 | 2900 | 60 | 87 | 37 | 3.5 | 91 | CIS125-100-315 | 2900 | 120 | 132.5 | 110 | 4 | 145 |

| 100 | 80 | 3.8 | 200 | 125 | 4.5 | ||||||||

| 120 | 74.5 | 4.8 | 240 | 120 | 5 | ||||||||

| 1450 | 30 | 21.3 | 5.5 | 2 | 1450 | 60 | 33.5 | 15 | 2.5 | ||||

| 50 | 20 | 2 | 100 | 32 | 2.5 | ||||||||

| 60 | 19 | 2.5 | 120 | 30.5 | 3 | ||||||||

| CIS100-65-250A | 2900 | 90 | 61 | 30 | 3.8 | CIS125-100-315A | 2900 | 180 | 97 | 90 | 4.5 | ||

| 1450 | 45 | 15.3 | 4 | 2 | 1450 | 90 | 24 | 11 | 2.5 | ||||

| CIS100-65-315 | 2900 | 60 | 133 | 75 | 3 | 120 | CIS125-100-400 | 1450 | 60 | 52 | 30 | 2.5 | 201 |

| 100 | 125 | 3.6 | 100 | 50 | 2.5 | ||||||||

| 120 | 118 | 4.2 | 120 | 48.5 | 3 | ||||||||

| 1450 | 30 | 34 | 11 | 2 | CIS125-100-400A | 1450 | 90 | 38 | 22 | 2.5 | |||

| 50 | 32 | 2 | |||||||||||

| 60 | 30 | 2.5 | CIS150-125-200 | 1450 | 120 | 14 | 11 | 3 | 118 | ||||

| CIS100-65-315A | 2900 | 90 | 97 | 55 | 3.6 | 200 | 12.5 | 3.2 | |||||

| 1450 | 45 | 24 | 7.5 | 2 | 240 | 11 | 3.5 | ||||||

| CIS125-100-200 | 2900 | 120 | 57.5 | 45 | 4.5 | 95 | CIS150-125-250 | 1450 | 120 | 22.5 | 18.5 | 3 | 140 |

| 200 | 50 | 4.5 | 200 | 20 | 3 | ||||||||

| 240 | 44.5 | 5 | 240 | 17.5 | 3.5 | ||||||||

| 1450 | 60 | 14.5 | 7.5 | 2.5 | CIS150-125-315 | 1450 | 120 | 34 | 30 | 2.5 | 188 | ||

| 100 | 12.5 | 2.5 | 200 | 32 | 2.5 | ||||||||

| 120 | 11 | 3 | 240 | 29 | 3 | ||||||||

| CIS125-100-200A | 2900 | 180 | 38 | 37 | 4.5 | 95 | CIS150-125-250A | 1450 | 180 | 15 | 15 | 3 | 140 |

| 1450 | 90 | 9.5 | 5.5 | 2.5 | |||||||||

| CIS200-150-250A | 1450 | 360 | 15 | 30 | 3.5 | 165 | CIS150-125-315A | 1450 | 180 | 24 | 22 | 2.5 | 188 |

| CIS150-125-400 | 1450 | 120 | 53 | 45 | 2 | 212 | CIS200-150-315 | 1450 | 240 | 37 | 55 | 3 | 237 |

| 200 | 50 | 2.8 | 400 | 32 | 3.5 | ||||||||

| 240 | 46 | 3.5 | 460 | 28.5 | 4 | ||||||||

| CIS150-125-400A | 1450 | 180 | 38 | 37 | 2.8 | CIS200-150-315A | 1450 | 360 | 24 | 45 | 3.5 | ||

| CIS200-200-200 | 1450 | 240 | 14.5 | 18.5 | 3.5 | 141 | CIS200-150-400 | 1450 | 240 | 55 | 90 | 3 | 245 |

| 400 | 12.5 | 4.2 | 400 | 50 | 3.8 | ||||||||

| 460 | 9.5 | 4.5 | 460 | 45 | 4.5 | ||||||||

| CIS200-150-250 | 1450 | 240 | 22.6 | 37 | 3.6 | 165 | CIS200-150-400A | 1450 | 360 | 38 | 75 | 3.8 | |

| 400 | 20 | 4.6 | |||||||||||

| 460 | 17.2 | 4.9 |

How to choose a marine horizontal centrifugal pump?

1) First, clarify the application and system type (determine pump type and requirements). Different applications of marine centrifugal pumps require different selection considerations:

Seawater cooling/firefighting/general seawater pumps: corrosion resistance, cavitation resistance, reliability, emergency power supply/self-priming requirements (firefighting often has specific regulations).

Freshwater circulation/central cooling/domestic water: corrosion resistance requirements are relatively low, but hygiene, noise, and efficiency must be considered.

Bottom/ballast/general transport: may contain impurities, gas, and operate intermittently; requires certain anti-clogging capabilities or lower NPSH requirements.

Fuel oil/lubricating oil transport: centrifugal pumps may not be suitable (efficiency drops significantly at high viscosity); gear/screw pumps are more suitable in many scenarios; if a centrifugal pump is insisted upon, viscosity correction and starting torque must be calculated.

2) Determine key operating parameters (determine hydraulic selection).

At least the following should be provided:

Flow rate Q: normal/maximum/minimum (m³/h). Head H: Includes static head + piping losses + valve/heat exchanger/filter pressure drop + margin (m).

Medium: Seawater/fresh water/oil/containing solids; temperature; density; whether it contains gas or sand.

Operating mode: Continuous/intermittent; whether parallel redundancy is required (common onboard “1 in use, 1 standby” or “2 × 50%”).

Selection principles (experience):

Ensure the operating point falls near the pump’s optimal efficiency point (BEP). It is generally recommended to operate within 70%–110% of the BEP flow rate to avoid prolonged low flow rates leading to overheating, vibration, and reduced bearing seal life.

When flow rate adjustment is required, prioritize variable frequency drives (VFDs) over long-term throttling.

3) Calculate suction conditions and cavitation margin (very critical for marine applications)

Calculate the NPSHa available from the system, ensuring that:

NPSHa ≥ NPSHr (pump sample) + safety margin (usually ≥0.5–1.0 m or as recommended by the classification society/manufacturer). Key factors affecting NPSHA:

* Suction head (pump centerline position relative to liquid level)

* Losses caused by suction pipe diameter, length, bends, and filters/seagates

* Medium temperature (higher temperatures increase cavitation risk). Seawater cooling pumps are often installed near seagates, where suction conditions are better; however, if the pump is positioned high or the suction piping is complex, cavitation should be carefully monitored.

4) Pump structure selection: Single-stage/multi-stage, end-suction/split-case, self-priming

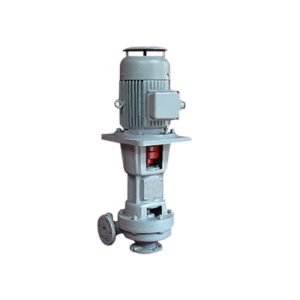

* Single-stage horizontal end-suction pump: Most common, simple structure, easy maintenance, suitable for low to medium head systems (cooling, general transport).

* Split-case (double-suction) pump: High flow rate, lower NPSH, easy maintenance, commonly used for high flow rates in fire fighting/ballast applications.

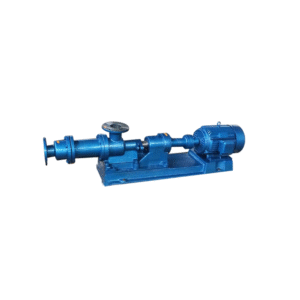

* Multi-stage centrifugal pump: High head requirements (e.g., boiler feedwater typically uses more specialized feedwater pump series).

* Self-priming capability: Centrifugal pumps are inherently not self-priming. If the system may have air intake or requires self-priming (e.g., some bilge systems, emergency pumping), a self-priming centrifugal pump or a priming device/vacuum priming should be selected.

5) Materials and Corrosion Protection (Highest Priority for Seawater Systems)

Materials Selection by Media:

Seawater: Common materials include bronze/aluminum bronze, duplex stainless steel (2205, etc.), and seawater-resistant cast iron with anti-corrosion coating (depending on grade and budget). The key is matching the impeller, pump body, and shaft sleeve materials to avoid electrochemical corrosion.

Freshwater: Ductile iron/cast iron with rust prevention treatment, stainless steel, etc.

Containing solids/sand: Wear-resistant materials, replaceable wear rings, reduced speed, or a more wear-resistant structure. Also consider: Sacrificial anode/insulation measures (common in seawater pumps)

Corrosion risks associated with pairing with other metals in the system.

6) Shaft Seal and Bearing Configuration (Related to Leakage and Lifespan)

Mechanical Seals: Mainstream for marine applications. For seawater, it is recommended to select suitable friction pairs (such as SiC/SiC, etc.) and flushing/cooling solutions.

Stuffing Seals: Simple structure but prone to leakage and frequent maintenance; gradually reduce their use.

Pay attention to the sealing chamber pressure and the risk of dry running (centrifugal pumps should not be run dry for extended periods). Bearings: Select vibration-resistant, long-life bearings, and confirm lubrication methods and installation direction limitations.

7) Drive, Electrical, and Control Systems (Must be compatible onboard)

Motor Power Supply: Common marine types include 440V/60Hz or 380V/50Hz; protection rating (IP), insulation class, and marine motor certification.

Speed/Frequency: Higher speeds at 60Hz will affect pump performance and NPSH (the same pump will show significant differences under 50/60Hz operating conditions).

Starting Method: Direct start/soft start/variable frequency; for high-power pumps, calculate the impact of starting current on the power grid.

Couplings and Base: Higher requirements for coaxiality and foundation rigidity are needed in ship vibration environments.

8) Classification Societies and Standards/Certifications (To avoid problems during later ship inspections)

Confirm whether the pump (and motor, control cabinet) requires and provide the corresponding certificates, such as:

Type approval from classification societies such as CCS / ABS / DNV / LR

Fire pumps may involve SOLAS/fire protection standards regarding flow rate, head, emergency power supply, and layout requirements.

9) Maintenance and Spare Parts (Onboard “Maintainability” is Important)

Is it a pull-out design (rotor components can be removed without disassembling the piping)?

Are vulnerable parts (mechanical seals, bearings, wear rings) universal, and what is their delivery time?

Are tools required, and how crew-friendly is it for maintenance?

Reviews

There are no reviews yet.