Description

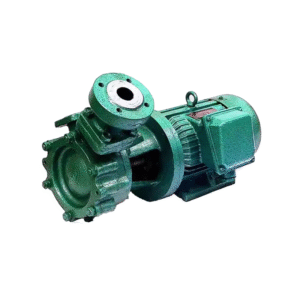

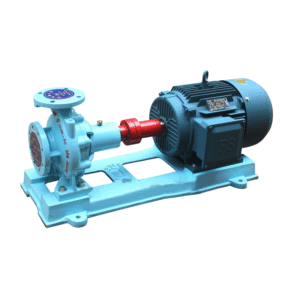

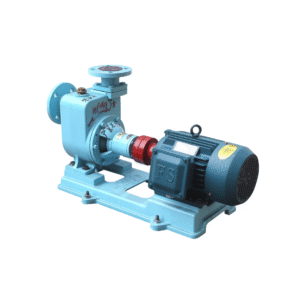

BA、CB Series marine horizontal centrifugal pump

一、 Overview

BA and CB type horizontal centrifugal pumps are suitable for transporting freshwater and seawater from sea and river vessels, and can be used as pumps for fire fighting, cooling, and sanitation. They can also be used for industrial and urban water supply and drainage; and for irrigation of farmland and orchards.

The BA pump uses a soft packing seal for its shaft seal, while the CB pump uses a mechanical seal. The performance parameters, shape, and installation dimensions of both types are identical.

The pump rotates counterclockwise when viewed from the drive end.

二、Main Technical Performance Parameters

Performance parameters when the power supply is 50Hz, 3φ, 380V:

| Model Specifications | Main technical parameter

(50Hz 3φ 380V) |

电机型号功率 kW |

泵组重量 Kg |

||||

| 流量 m3/h |

扬程 m |

转速 r/min |

汽蚀余量 NPSHr m |

轴功率 kW |

|||

| 11/2BA-6 | 6 | 20.3 | 2900 | 6.6 | 0.745 | Y90S-2H 1.5 | 26 |

| 11 | 17.4 | 6.7 | 0.923 | ||||

| 14 | 14 | 6.0 | 1.01 | ||||

| 11/2BA-6A | 5 | 16 | 6.5 | 0.578 | |||

| 9.5 | 14.2 | 6.9 | 0.713 | ||||

| 13.5 | 11.2 | 6.1 | 0.825 | ||||

| 11/2 BA-6B | 4.5 | 12.8 | 6.4 | 0.448 | Y802-2H 1.1 | ||

| 9 | 11.4 | 7.0 | 0.57 | ||||

| 13 | 8.8 | 6.3 | 0.693 | ||||

| 2BA-6 | 10 | 34.5 | 8.2 | 1.87 | Y112M-2H 4 | 43 | |

| 20 | 30.8 | 7.2 | 2.62 | ||||

| 30 | 24 | 5.7 | 3.09 | ||||

| 2BA-6A | 10 | 28.5 | 8.2 | 1.44 | Y100L-2H 3 | ||

| 20 | 25.2 | 7.2 | 2.07 | ||||

| 30 | 20 | 5.7 | 2.55 | ||||

| 2BA-6B | 10 | 22 | 8.2 | 1.10 | Y90L-2H 2.2 | ||

| 20 | 18.8 | 7.2 | 1.57 | ||||

| 25 | 16.3 | 6.6 | 1.73 | ||||

| 2BA-9 | 11 | 21 | 8.0 | 1.12 | 38 | ||

| 20 | 18.5 | 6.8 | 1.47 | ||||

| 25 | 16 | 6.0 | 1.66 | ||||

| 2BA-9A | 10 | 16.8 | 8.1 | 0.85 | Y90L-2H 2.2 | 38 | |

| 17 | 15 | 7.3 | 1.06 | ||||

| 22 | 13 | 6.5 | 1.23 | ||||

| 2BA-9B | 10 | 13 | 2900 | 8.1 | 0.70 | Y90S-2H 1.5 | 38 |

| 15 | 12 | 7.6 | 0.82 | ||||

| 20 | 10.3 | 9.8 | 0.91 | ||||

| 3BA-6 | 30 | 62 | 7.7 | 9.3 | Y160M2-2H 15 | 116 | |

| 45 | 57 | 6.7 | 11.0 | ||||

| 60 | 50 | 5.6 | 12.3 | ||||

| 70 | 44.5 | 4.7 | 13.3 | ||||

| 3BA-6A | 30 | 45 | 7.5 | 6.65 | Y160M1-2H 11 | ||

| 40 | 41.5 | 7.1 | 7.38 | ||||

| 50 | 37 | 6.4 | 7.98 | ||||

| 60 | 30 | 8.8 | |||||

| 3BA-9 | 30 | 35.5 | 7.0 | 4.66 | Y132S2-2H 7.5 | 60 | |

| 45 | 32.6 | 5.0 | 5.56 | ||||

| 55 | 28.8 | 3.0 | 6.32 | ||||

| 3BA-9A | 25 | 21.5 | 7.0 | 2.83 | Y112M-2H 4 | ||

| 35 | 19.7 | 6.4 | 3.35 | ||||

| 45 | 17.4 | 5.0 | 3.87 | ||||

| 3BA-13 | 32.4 | 21.5 | 6.5 | 2.5 | 41 | ||

| 45.0 | 18.8 | 5.5 | 2.88 | ||||

| 52.2 | 15.6 | 5.0 | 2.96 | ||||

| 3BA-13A | 29.5 | 17.4 | 6.0 | 1.86 | |||

| 39.6 | 15.0 | 5.0 | 2.02 | ||||

| 48.6 | 12.0 | 4.5 | 2.15 | ||||

| 3BA-13B | 28 | 13.5 | 5.5 | 1.63 | Y90L-2H 2.2 | ||

| 34.2 | 12 | 5.0 | 1.72 | ||||

| 41.5 | 9.5 | 4.0 | 1.73 | ||||

| 4BA-6 | 65 | 98 | 7.1 | 27.6 | Y250M-2H 55 | 138 | |

| 90 | 91 | 6.2 | 32.8 | ||||

| 115 | 81 | 5.1 | 37.1 | ||||

| 135 | 72.5 | 4.0 | 40.4 | ||||

| 4BA-6A | 65 | 82 | 7.1 | 22.9 | Y200L2-2H 37 | ||

| 85 | 76 | 6.4 | 26.1 | ||||

| 105 | 69.5 | 5.5 | 29.1 | ||||

| 125 | 61.6 | 4.6 | 31.7 | ||||

| 4BA-8 | 70 | 59 | 5.0 | 17.5 | Y200L1-2H 30 | 116 | |

| 90 | 54.2 | 4.5 | 19.3 | ||||

| 109 | 47.8 | 3.8 | 20.6 | ||||

| 120 | 43 | 3.5 | 21.4 | ||||

| 4BA-8A | 70 | 48 | 5.0 | 13.6 | Y180M-2H 22 | ||

| 90 | 43 | 4.5 | 15.3 | ||||

| 109 | 36.8 | 3.3 | 16.8 | ||||

| 4BA-12 | 65 | 37.7 | 6.7 | 9.25 | Y160M2-2H 15 | 108 | |

| 90 | 34.6 | 5.8 | 10.8 | ||||

| 120 | 28 | 3.3 | 12.3 | ||||

| 4BA-12A | 60 | 31.6 | 6.9 | 7.4 | Y160M1-2H 11 | 108 | |

| 85 | 28.6 | 6.0 | 8.4 | ||||

| 110 | 23.3 | 4.5 | 9.5 | ||||

| 4BA-18 | 65 | 22.6 | 5.32 | 65 | |||

| 90 | 20 | 5 | 6.28 | ||||

| 110 | 17.1 | 6.93 | |||||

| 4BA-18A | 60 | 17.2 | 3.80 | Y132S2-2H 7.5 | |||

| 80 | 15.2 | 4.35 | |||||

| 95 | 13.2 | 4.80 | |||||

| 4BA-25 | 54 | 17.6 | 2900 | 5 | 3.69 | Y132S1-2H 5.5 | 44 |

| 79 | 14.8 | 4.10 | |||||

| 99 | 10 | 4.02 | |||||

| 4BA-25A | 50 | 14 | 2.80 | Y112M-2H 4 | |||

| 72 | 11 | 2.87 | |||||

| 86 | 8.5 | 2.78 | |||||

| 6BA-8 | 110 | 36.5 | 1450 | 6.6 | 15.6 | Y200L-4H 30 | 166 |

| 140 | 35.9 | 6.3 | 18.3 | ||||

| 170 | 32.5 | 5.9 | 19.7 | ||||

| 200 | 29.2 | 5.2 | 21.4 | ||||

| 6BA-8A | 110 | 30.5 | 6.6 | 12.7 | Y180L-4H 22 | ||

| 140 | 28.6 | 6.3 | 14.8 | ||||

| 170 | 25.8 | 5.9 | 15.7 | ||||

| 200 | 21.3 | 5.2 | 16.7 | ||||

| 6BA-8B | 110 | 24.4 | 6.6 | 10.2 | Y160L-4H 15 | ||

| 140 | 22.0 | 6.3 | 11.3 | ||||

| 180 | 18.1 | 5.9 | 13.6 | ||||

| 6BA-12 | 110 | 22.7 | 8.5 | 8.96 | Y160L-4H 15 | 146 | |

| 160 | 20.1 | 7.9 | 10.8 | ||||

| 200 | 17.1 | 7.0 | 11.8 | ||||

| 6BA-12A | 95 | 17.8 | 8.6 | 6.18 | Y160M-4H 11 | ||

| 150 | 15 | 8 | 7.69 | ||||

| 180 | 12.6 | 7.6 | 8.07 | ||||

| 6BA-18 | 126 | 14.3 | 6.0 | 6.3 | Y132M-4H 7.5 | 134 | |

| 162 | 12.5 | 5.5 | 6.50 | ||||

| 187 | 9.6 | 5.0 | 6.62 | ||||

| 6BA-18A | 115 | 11 | 6.0 | 4.93 | |||

| 144 | 9.5 | 5.5 | 5.03 | ||||

| 162 | 8 | 5.0 | 5.18 | ||||

| 8BA-12 | 220 | 32 | 6.5 | 24 | Y225S-4H 37 | 191 | |

| 280 | 29.1 | 5.6 | 26.9 | ||||

| 340 | 25.4 | 4.7 | 29.4 | ||||

| 8BA-12A | 220 | 26 | 6.7 | 17.1 | Y200L-4H 30 | ||

| 250 | 24 | 6.1 | 20.1 | ||||

| 290 | 21.8 | 5.5 | 21.2 | ||||

| 8BA-18 | 220 | 20 | 6.2 | 14.9 | Y180L-4H 22 | 180 | |

| 285 | 18 | 5.5 | 16.6 | ||||

| 360 | 14 | 5.0 | 17.5 | ||||

| 8BA-18A | 220 | 17.5 | 11.9 | Y160L-4H 15 | |||

| 260 | 15.7 | 5.8 | 13.3 | ||||

| 320 | 12.7 | 13.9 | |||||

| 8BA-25 | 216 | 14.5 | 5.5 | 10.6 | 143 | ||

| 270 | 12.7 | 5.0 | 11.3 | ||||

| 324 | 11.0 | 4.5 | 11.8 | ||||

| 8BA-25A | 191 | 11.4 | 5.0 | 7.68 | Y160M-4H 11 | ||

| 238 | 9.9 | 4.5 | 8.00 | ||||

| 285 | 8.6 | 4.0 | 8.56 | ||||

How to select a marine horizontal centrifugal pump?

1) Define Operating Conditions (Determine the Pump’s Hydraulic Point)

Application/System: Seawater cooling, freshwater circulation, ballast, bilge, fire fighting, general transport, etc. (Different applications have different requirements for corrosion resistance, self-priming, and specifications).

Flow Rate Q (m³/h): Normal/Maximum/Minimum, whether adjustment is required.

Head H (m): Static head + pipeline friction/local losses + heat exchanger/filter/valve pressure drop + margin.

Medium: Seawater/Freshwater/Oil; Temperature, density, viscosity, presence of sand/impurities/gas.

Selection Goal: To ensure the operating point falls as close as possible to the pump’s Optimal Efficiency Point (BEP) on its curve. Long-term operation is generally recommended within approximately 70%–110% of the BEP flow rate.

2) Suction Conditions and Cavitation (Very Critical for Marine Applications)

Calculate the NPSHa available from the system (determined by liquid level, suction pipe losses, medium temperature/saturated vapor pressure, etc.). To meet the following requirements: NPSHa ≥ NPSHr (as per the sample) + margin (usually 0.5–1 m or as recommended by the classification society/manufacturer).

Suction piping should be as short, straight, and with few bends as possible to minimize suction-side resistance. Appropriately increase the suction inlet diameter to reduce pressure drop caused by filters/seagates. Avoid installing the pump too high, which could lead to suction head conditions (especially since warm water/seawater is more prone to cavitation).

3) Pump structure selection (related to flow rate, head, and maintenance)

Common horizontal centrifugal pump structure selections:

Single-stage end-suction horizontal pump: General-purpose first choice (medium to low head, easy maintenance).

Split-case (double-suction) pump: High flow rate, lower NPSH, easy maintenance (common in fire fighting/ballast).

Multi-stage horizontal pump: High head requirements (e.g., special feedwater/high-pressure delivery).

Self-priming required: Ordinary centrifugal pumps do not self-prime; if air intake or self-priming is possible in bilge/emergency pumping, a self-priming centrifugal pump or a priming device should be selected.

4) Materials and Corrosion Protection (Key Focus for Seawater Pumps)

Seawater: Prioritize aluminum bronze/bronze, duplex stainless steel (e.g., 2205), and seawater-resistant cast iron with a reliable anti-corrosion coating; ensure compatibility with the system metals for galvanic corrosion, and implement sacrificial anode/insulation measures if necessary.

Freshwater: Cast iron/ductile iron with rust prevention or stainless steel.

Sand/Impurities: Wear-resistant materials, replaceable wear rings/wear-resistant rings; reduce speed if necessary.

5) Shaft Seal and Reliability

Mechanical seals are the mainstream: Select friction pairs according to the medium (seawater often uses more wear-resistant and corrosion-resistant combinations); implement flushing/cooling solutions if necessary.

Consider: Whether short-term dry running is permissible (mostly not), seal cavity pressure, and ease of maintenance.

Marine environments experience significant vibration, requiring higher standards for bearings and alignment; base rigidity and installation quality are crucial.

6) Drive and Control (Confirm 50/60Hz Difference)

Electrical System: **Voltage/Frequency (50/60Hz)** determines the speed, affecting the pump’s Q/H/NPSH.

Adjustment Method: Variable frequency speed control is preferred, as it is more energy-efficient and pump-friendly than long-term flow throttling.

Starting Method: For high-power applications, consider soft start/variable frequency conversion, and calculate the impact of starting current on the ship’s network.

7) Classification Society and Standards: Confirm whether type approvals or inspection certificates such as CCS/ABS/DNV/LR are required based on ship requirements.

Fire pumps typically have specifications regarding rated flow, head, emergency power supply/layout, etc., which need to be checked in advance.

8) Maintenance and Spare Parts: Prioritize **back pull-out** structure: Allows for core removal and maintenance without dismantling the piping.

Confirm the supply cycle and universality of vulnerable parts (mechanical seals, bearings, wear rings); ships often use a “one in use, one standby” redundancy system.

Reviews

There are no reviews yet.